- Publicatie 24 April 2022

![]()

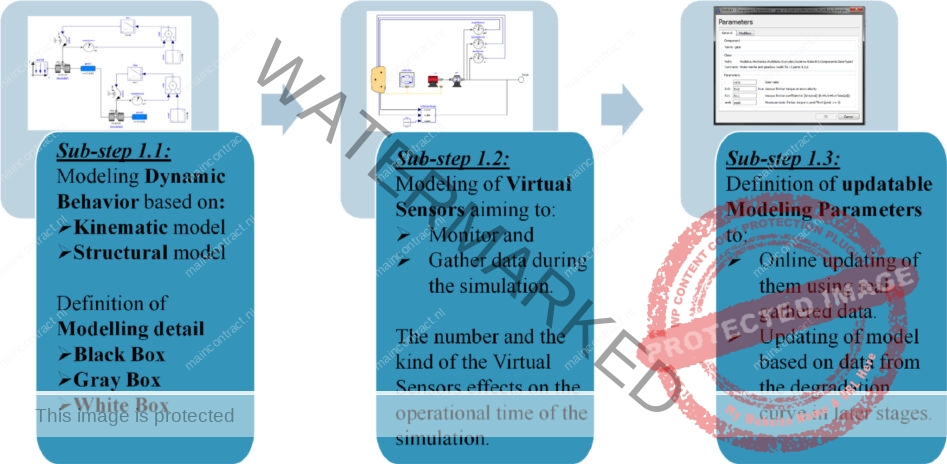

Predictive maintenance has been proposed to maximize the overall plant availability of modern manufacturing systems. To this end, research has been conducted mainly on data-driven prognostic techniques for machinery equipment individual components. However, the lack of historical data together with the intricate design of industrial machines, e.g. robots, stimulate the use of advanced methods exploiting simulation capabilities. This paper aims to address this challenge by introducing a generic framework for the enhancement of advanced physics-based models with degradation curves.

The creation of a robot’s simulation model and its enrichment with data from the degradation curves of the robot’s components is presented. Following, the extraction of information from degradation curves during the simulation of the robot’s dynamic behaviour is addressed. The Digital Twin concept is employed to monitor the health status of the robot and ensure the convergence of the simulated to the actual robot behaviour. The output of the simulation can enable to estimate the future behaviour of the robot and make predictions for the quality of the products to be produced, as well as to estimate the robot’s Remaining Useful Life.

![]()

Authos: P. Aivaliotis, Z. Arkouli, K. Georgoulias and S. Makris

Paper presented at 46th ESReDA Seminar on Reliability Assessment and Life Cycle Analysis of Structures and Infrastructures (May 29th – 30th, 2014) Politecnico di Torino, Turino, Italy

Modern manufacturing systems rely on machinery equipment which tends to be highly robust and with a long lifetime e.g. on average approximately 10 years for an industrial robot. Nevertheless, material defects, tolerances, overloading, vibrations, humidity, fatigue, or other factors will eventually cause performance degradation. This may lead to quality deterioration or halts of production due to sudden failures. Considering that a one-day halt may cost up to 100000 or 200000 euros, as well as that maintenance costs can account for approximately up to 60% even 70% of production lifecycle costs it seems that maintenance management optimization is a key activity determining a company’s competitive position.

Modern manufacturing systems rely on machinery equipment which tends to be highly robust and with a long lifetime e.g. on average approximately 10 years for an industrial robot. Nevertheless, material defects, tolerances, overloading, vibrations, humidity, fatigue, or other factors will eventually cause performance degradation. This may lead to quality deterioration or halts of production due to sudden failures. Considering that a one-day halt may cost up to 100000 or 200000 euros, as well as that maintenance costs can account for approximately up to 60% even 70% of production lifecycle costs it seems that maintenance management optimization is a key activity determining a company’s competitive position.

maintenance activities. Research around PdM includes diagnostics, which investigate or analyze the cause of a failure after it has occurred, and prognostics which model the degradation processes in order to predict the future state or the Remaining Useful Life of a machine or machine’s individual components. Three main approaches of modelling degradation exist; knowledge-based (which use expert or fuzzy systems to model degradation effects based on a database of previously defined failures), physical model-based (which use mathematical models to describe the degradation process), and data-driven (which usually employ Neural Networks, regression, filtering, and stochastic models, etc.), but also combinations of the approaches to improve the overall prognosis performance .

Degradation curves that are useful for health status prediction may derive from prognostics or by collecting data via Condition Monitoring techniques. Indicative studies involve fiducial markers with data-driven models to estimate position deviations of an industrial robot’s end-effector due to degradation, fuzzy sets to examine the degradation of power plant components, and spall propagation modelling for the prediction deterioration effect on propulsion system bearings.

![]()

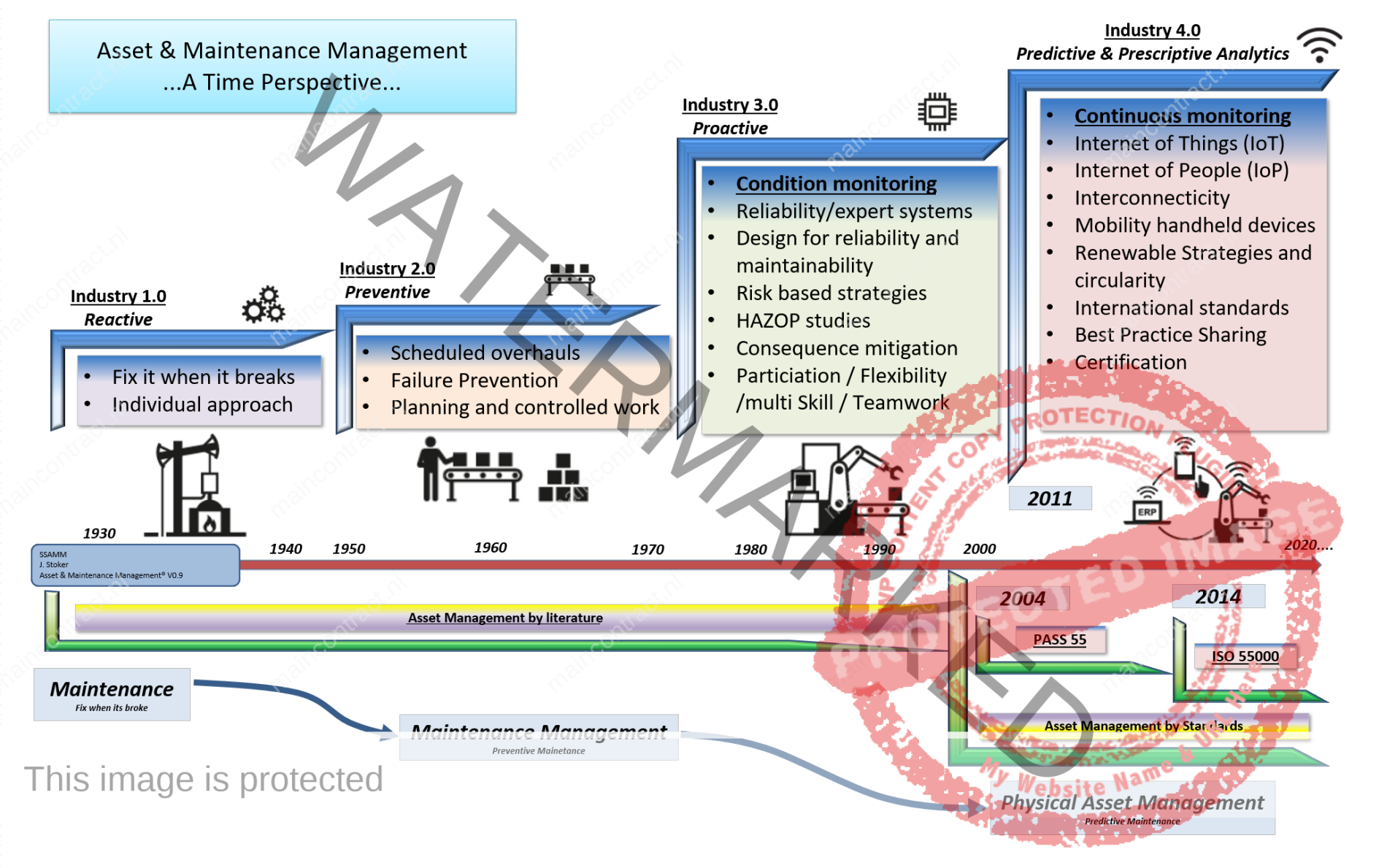

Click to enlarge: Asset & Maintenanec Management-A time perspective by Jan Stoker

A common problem limiting the degradation curves creation studies is the lack of failure data, as the industrial and military communities would rarely allow their machinery equipment to run to failure, as well as the long time needed until significant changes in systems state variables is observed. To this end, accelerated tests have been employed aiming to provide the required data within a practical experiment length. Accelerated tests have been proposed to investigate the wear effects of gear pumps [23], RV reducers, rotary encoders, and harmonic drives.

This research focuses on presenting a methodology of integrating degradation profiles in physics-based digital models for predictive maintenance of industrial robots. The proposed methodology comprises four steps. The aim of these steps is to adequately represent the future behaviour of the robot taking into account its kinematics, as well as its structural characteristics but also the main physical phenomena affecting its response e.g. friction, elasticity, hysteresis, etc. Even though the dynamic behaviour of robots may also deteriorate due to electrical phenomena such as loose connections, short circuits, electrical overload etc., this study will focus on degradation induced by the robot’s mechanical parts e.g. gears, bearings, shafts, pumps, etc.

![]()

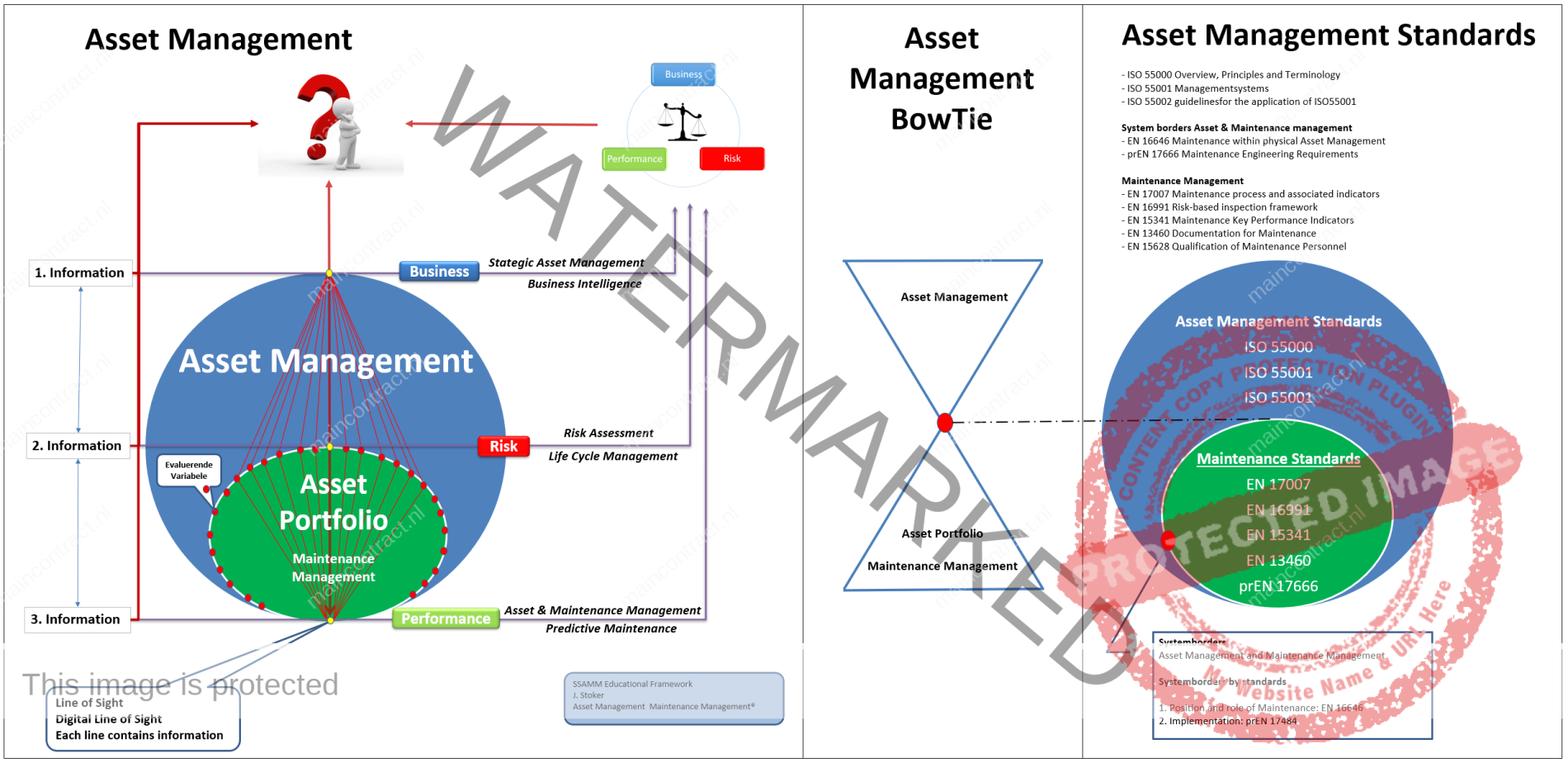

The recently published standard EN 17485 introduces methods and procedures about maintenance within physical asset management for all the levels and functions of the organizations’ management, including corporate planning management, plant management, technical management, production management, financial management, asset management, maintenance management, and quality management. Further and maybe even greater benefits are now being found through improved credibility in the eyes of customers, regulators and other stakeholders.

Click to enlarge

Physical asset management also results in much greater engagement and motivation of the workforce, and in more sustainable, continual improvement business processes. Physical asset management builds up the required link between maintenance management and the organizational strategic plan and gives direction to maintenance activities.The standards EN 16646 and EN 17485 build the bridge between ISO 5500x (Asset management system standards) and the EN maintenance standards. ISO 55001 states that organizations should determine e.g. the organizational context, requirements for the assets, decision criteria, strategic asset management plan and asset management plan (including maintenance).

However, it does not describe how to do it. Respectively, maintenance standards often introduce e.g. the concept of the required function or the concept of maintenance strategy, but do not explain how they have been determined. EN 17485 introduces a methodological framework which advises organizations to implement the requirements presented in ISO 55001. By doing this it creates the bridge between the several maintenance standards and ISO 5500x in order to give an applicable starting point to the more detailed documents for the specific sub-functions of maintenance (See AM-BowTie).

This insights, the Asset Management BowTie, can be added toward the Asset Management paradigm with the (Digital) Line of Sit. To add the BowTie principle, the body of thoughts of the EN-17485 can be incorporated in the Asset Management paradigm with the mentioned standards. Result is a deepened figure 1 of the ISO5500 completed with the Line(s) of Sights, the levels of information, Business, Risk Assessment and Asset & Maintenance going to decision making in balancing Costs, Risks and Performance.

Click to enlare Asset Management BowTie: See Body of thoughts AM-BowTie Click Here

![]()

The research presented a methodology for the integration of degradation curves to physics-based models for predictive maintenance. The four steps included in this approach have been successfully applied in a case study for the prediction of a robot’s RUL. The digital model creation has been performed using OpenModelica, literature review in tandem with maintenance historical data, and manufacturer data have been combined to identify the most prone to failure robot component, which seems to be the gearbox. In addition, the bearings were considered the weakest element of the gearbox. Friction was the selected governing degradation phenomenon that was studied. In particular, the Coulomb friction of coefficient has been selected as the parameter capturing the bearings deterioration, which seems reasonable since it has been assumed that the lubrication will deteriorate to a point where metal-to- metal contact will occur. The Digital Twin concept has been employed to

tune the modelling parameters to the actual condition of the robot, to enable more accurate predictions of the future condition of the robot. The results of the proposed methodology show that it is possible to estimate the future dynamic behaviour of a robot as well as its RUL by simulating its enhanced digital model for future time intervals. The duration of the RUL algorithm execution was too long (approximately 30 seconds per loop) to allow a real-time prediction. However, this does not constitute a limitation because the authors aimed to provide a methodology for long-term predictions towards resource planning, maintenance scheduling, and spare parts ordering optimization. It is possible to reduce the runtime of the process, by selecting faster software packages, improving the calculation algorithms, and employing a dynamic time step that will adapt to the deviation of the predicted and the nominal signals. The future work of the authors will include among others: the modelling of the gears’ friction and backlash as they also seem to be responsible for a great percentage of rotary machinery failures, further investigation on the degradation curves because friction and wear are complex phenomena which are difficult to capture by simple monotonic curves. The authors will also re-examine the use of the Coulomb-viscous friction model as it might be oversimplified. Finally, the authors intend to plan accelerated experiments in order to validate the precision of the suggested approach, as well as to collect data from the industrial application to validate their predictions.

Click to enlarge

![]()

5. React, Discuss & Article

Discuss or give your opinionFollow on FacebookFollow on Twitter

Related Articles