- Publication 3 April 2022

Sources

- Nowlan & Heap Publication 1978

- RCM Gateway to to World class maintenance Smith & Hinchclife

- RCM II J. Moubray

- RCM III M. Bason

- EN 60300 2009 RCM

- JA101 & JA1012

![]()

The goal of an effective maintenance organization is to provide the required system performance at the lowest cost. This means that the maintenance approach must be based upon a clear understanding of failure at each of the system levels.

System components can be degraded or even failed and still not cause a system failure. For example, a failed parking lamp on an automobile has little effect on the overall performance of the automobile of the car as a transportation system.

![]()

Authors & Review: SSAMM, Review: J. Stoker

Each of us has some intuitive notion of what constitutes a failure. We would all agree that an automobile engine, a fuel pump, or a tire has functional failure failed if it ceases to perform its intended function. But there are times potential failure when an item does continue to function, although not at its expected level. An automobile engine may run powerfully and smoothly, but its oil consumption is high; a fuel pump may pump fuel, but sluggishly; a tire may hold air and support the car, but its bald tread indicates that it will do neither much longer. Have these items failed? If not, how bad must their condition become before we would say a failure has occurred? Moreover, if any of these conditions is corrected, the time required for unanticipated repairs might force a change in other plans, such as the delay or cancellation of a trip. In this event could it still be argued that no failure had occurred? To cover all these eventualities we can define a failure in broad terms as follows:

A Failure is an Unsatisfactory condition

In other words, a failure is any identifiable deviation from the original condition which is unsatisfactory to a particular user. The determination that a condition is unsatisfactory, however, depends on the consequences of failure in a given operating context.

![]()

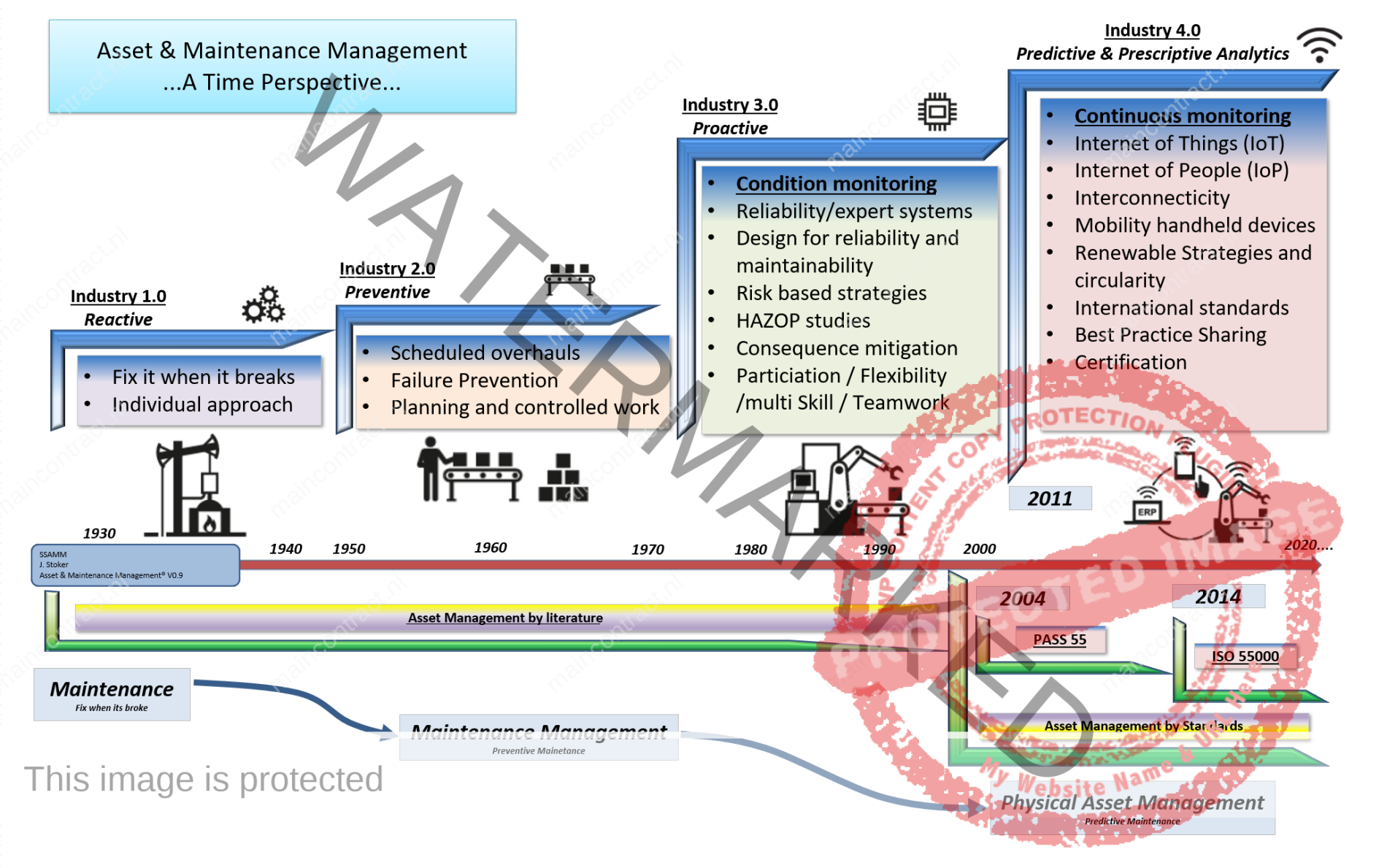

Click to enlarge: Asset & Maintenanec Management-A time perspective by Jan Stoker

For example, high oil consumption in an aircraft engine may pose no problem on short or medium-range flights, whereas on long-range flights the same rate of consumption would exhaust the oil supply. Similarly, engine instrument malfunctions that would not disrupt operations on multiengine equipment would be clearly unsatisfactory on a single-engine plane, and performance that is acceptable in a land-based environment might not be good enough for carrier operation.

In short, the exact dividing line between satisfactory and unsatisfactory conditions will depend not only on the function of the item in question, but on the nature of the equipment in which it is installed and the operating context in which that equipment is used. The determination will therefore vary from one operating organization to another. Within a given organization, however, it is essential hat the boundaries between satisfactory and unsatisfactory conditions be defined for each item in clear and unmistakable terms.

![]()

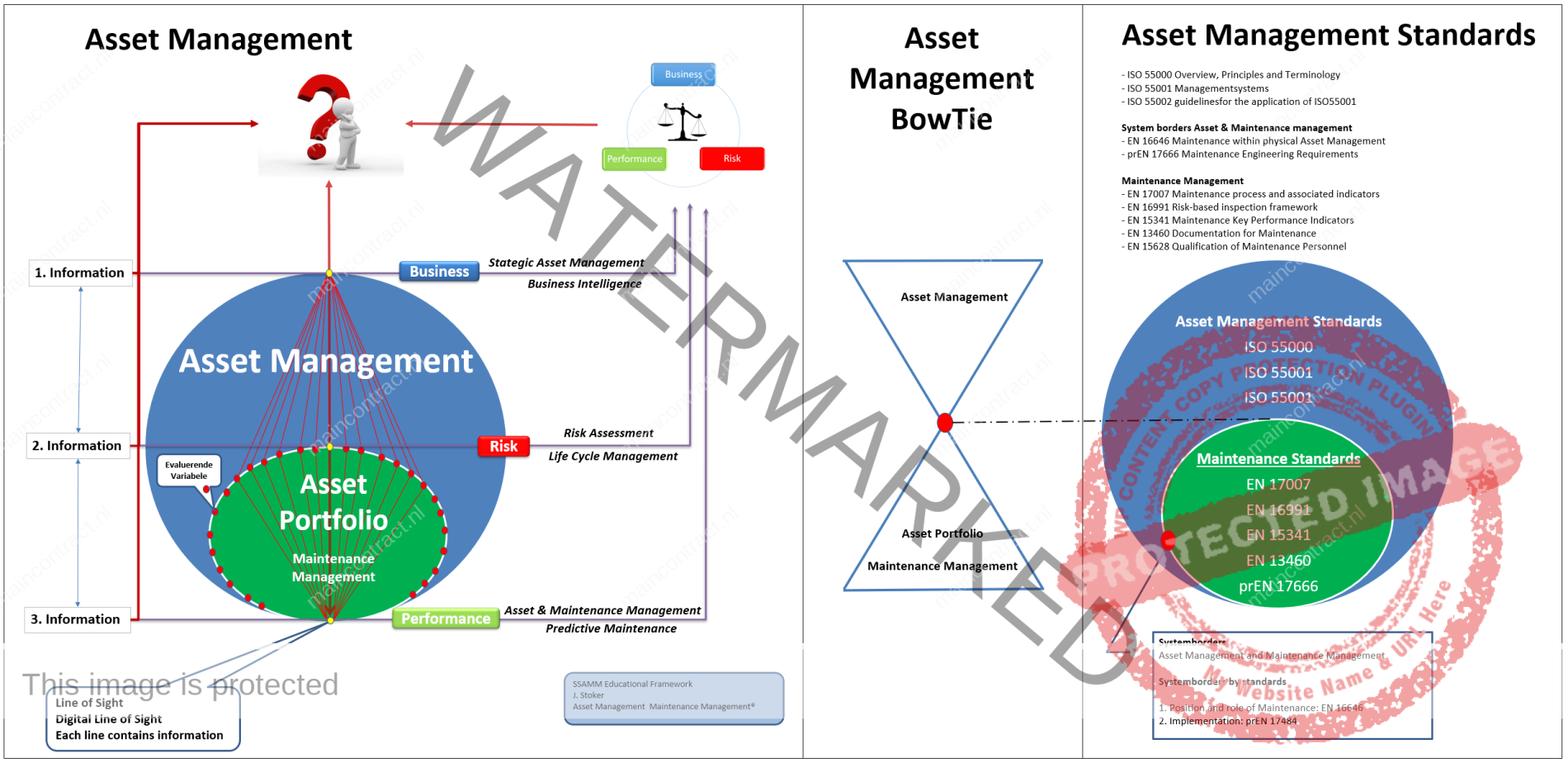

The recently published standard EN 17485 introduces methods and procedures about maintenance within physical asset management for all the levels and functions of the organizations’ management, including corporate planning management, plant management, technical management, production management, financial management, asset management, maintenance management, and quality management. Further and maybe even greater benefits are now being found through improved credibility in the eyes of customers, regulators and other stakeholders.

Click to enlarge

Physical asset management also results in much greater engagement and motivation of the workforce, and in more sustainable, continual improvement business processes. Physical asset management builds up the required link between maintenance management and the organizational strategic plan and gives direction to maintenance activities.The standards EN 16646 and EN 17485 build the bridge between ISO 5500x (Asset management system standards) and the EN maintenance standards. ISO 55001 states that organizations should determine e.g. the organizational context, requirements for the assets, decision criteria, strategic asset management plan and asset management plan (including maintenance).

However, it does not describe how to do it. Respectively, maintenance standards often introduce e.g. the concept of the required function or the concept of maintenance strategy, but do not explain how they have been determined. EN 17485 introduces a methodological framework which advises organizations to implement the requirements presented in ISO 55001. By doing this it creates the bridge between the several maintenance standards and ISO 5500x in order to give an applicable starting point to the more detailed documents for the specific sub-functions of maintenance (See AM-BowTie).

This insights, the Asset Management BowTie, can be added toward the Asset Management paradigm with the (Digital) Line of Sit. To add the BowTie principle, the body of thoughts of the EN-17485 can be incorporated in the Asset Management paradigm with the mentioned standards. Result is a deepened figure 1 of the ISO5500 completed with the Line(s) of Sights, the levels of information, Business, Risk Assessment and Asset & Maintenance going to decision making in balancing Costs, Risks and Performance.

Click to enlare Asset Management BowTie: See Body of thoughts AM-BowTie Click Here

![]()

Functional Failure

The judgment that a condition is unsatisfactory implies that there must be some condition or performance standard on which this judgment can be based. As we have seen, however, an unsatisfactory condition can range from the complete inability of an item to perform its intended function to some physical evidence that it will soon be unable to do so. For maintenance purposes, therefore, we must classify failures further as either functional failures or potential failures:

A functional failure is the inability of an item (or the equipment containing it) to meet a specified performance standard.

A complete loss of function is clearly a functional failure. Note, however, that a functional failure also includes the inability of an item to function at the level of performance that has been specified as satisfactory. This definition thus provides us with an identifiable and measurable condition, a basis for identifying functional failures. To define a functional failure for any item we must, of course, have a clear understanding of its functions. This is not a trivial consideration. For example, if we say that the function of the braking system on an airplane is to stop the plane, then only one functional failure is possible inability to stop the plane.

However, this system also has the functions of providing modulated stopping capability, providing differential braking for maneuvering on the ground, providing antis kid capability, and so on. With this expanded definition, it becomes clear that the braking system is in fact subject to a number of different functional failures. It is extremely important to determine all the functions of an item that are significant in a given operating context, since it is only in these terms that its functional failures can be defined.

Potential Failure

Once a particular functional failure has been defined, some physical condition can often be identified which indicates that this failure is imminent. Under these circumstances it may be possible to remove the item from service before the point of functional failure. When such conditions can be identified, they are defined as potential failures

A potential failure is an identifiable physical condition which indicates a functional failure is imminent.

The fact that potential failures can be identified is an important aspect of modem maintenance theory, because it permits maximum use of each item without the consequences associated with a functional failure. Units are removed or repaired at the potential-failure stage, so that potential failures preempt functional failures. For some items the identifiable condition that indicates imminent failure is directly related to the performance criterion that defines the functional failure. For example, one of the functions of a tire tread is to provide a renewable surface that protects the carcass of the tire so that it can be retreaded.

This function is not the most obvious one, and it might well be overlooked in a listing of tire functions; nevertheless, it is important from an economic standpoint. Repeated use of the tire wears away the tread, and if wear continues to the point at which the carcass cannot be retreaded, a functional failure has occurred. To prevent this particular functional failure, we must therefore define the potential failure as some wear level that does not endanger the carcass. The ability to identify either a functional or a potential failure thus depends on three factors:

- Clear definitions of the functions of an item as they relate to the equipment or operating context in which the item is to be used

- A clear definition of the conditions that constitute a functional failure in each case

- A clear definition of the conditions that indicate the imminence of this failure

In other words, we must not only define the failure; we must also specify the precise evidence by which it can be recognized.

Click to enlarge

Click for the SSAMM Education programs

![]()

5. React, Discuss & Article

Discuss or give your opinionFollow on FacebookFollow on Twitter

Related Articles

Tags: NEN-ISO 55000, Risk