Pagina Inhoud

![]()

Decision makers often find it difficult to determine priorities in operations, replacement and maintenance decisions for large quantities of devices within different departments. The rationale on which decisions are made are often unknown, implicit or do not share the same interests. This can lead to biased decision making and does not contribute to the goal of the organization.This study proposes a tool to prioritize the criticality of devices for operations

using the analytic hierarchy process (AHP). This method reduces complex decisions into a series of comparisons and rankings. It helps eliminating bias and provides a clear rationale for the decision making. By using heuristic reasoning, proposals for replacements and maintenance concepts are made based on predetermined criteria. In addition the assortment management risks are indicated for each device.

![]()

Author: Matthieu Verbogt Maintenance Engineering 983 Squadron, Royal Netherlands Airforce, Hoogerheide

1st Thesis Supervisor : C.F.H. van Rijn

To perform maintenance on aircrafts and aircraft components approximately 33,000 workshop equipment, tools and production machines are used within the Logistic Centre Woensdrecht. Approximately 18,500 of these devices are subject to (preventive) maintenance. Devices are considered to be not available if they cannot fulfil their function due to a defect or if performance standards are not met. Besides this, according to military aviation maintenance regulations, devices can only be used for the execution of maintenance if the due date of preventive maintenance has not been expired. To on time deliver maintained aircrafts and aircraft components for the Airforce it is crucial to manage (un)availability of workshop equipment, tools and production machines.

Source: Wissekerkentechniek.nl

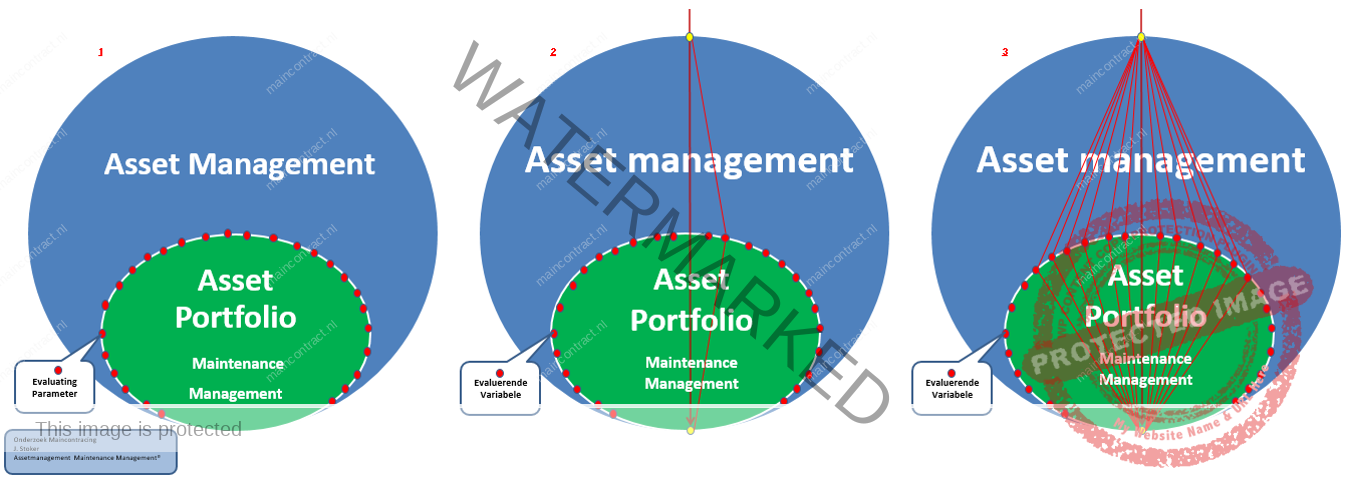

II-Asset Management

Asset management systems like ISO-55000 series are intended to manage risks and opportunities to achieve the desired balance between costs, risks and performance of assets over their life cycle (Normcommissie 400 183 “Asset Management”, 2014). Organizations have to fill the content by

Click to enlarge. Article; Line of Sight : Deepening the subject

themselves to make decisions based on the needed information in line with the goals for assets. Although this seems a logical base, in practice it turns out that organizations find it difficult to define clear goals for assets. If goals are not clearly defined it is not clear in all layers of the organization what information is needed to make good decision in line with the goal. Over time organizations have to deal with uncertainty in supply and demand of workload, failure of assets or human failures. It is important to identify and estimate the impact and probability to decrease or mitigate risks.

III – Risk management

Good asset management can be considered as managing risks. Riskmanagement is an important foundation in asset management; it focusses on covering the lifecycle management of assets that are the core to an organization’s purpose. For identifying core assets and ranking potential undesired events by importance a risk-based criticality meth-od is an essential tool (The Institution of Civil Engineers, 2010). Riskmanagement systems like NEN-ISO 31010 provide guidance on selection and application of systematic techniques for risk assessment. It does not provide specific criteria for identifying the need for risk analysis, nor it does specify the type of risk analysis method that is required for a particular application (Normcommissie 400 178 “Riskmanagement – Risk assessment techniques”, 2009). This means organizations have to establish the context in line with the organization’s strategy and have to classify the risk criteria themselves. Based on the context and classified criteria the most suitable risk analysis method should be selected to perform a risk assessment.

IV – Risk management techniques

Criticality analysis is applied in various areas and commonly focuses on predetermined key elements that are important to an organization, sector, discipline or product. Researchers acknowledge the need to identify critical assets and infrastructures but leave it up to individual companies to determine the specific basis for criticality in their assessments (Moteff and Parfomak, 2004, CRS-13; Moss and Woodhouse, 1999; Crespo Márquez, Moreau de León, Gómez Fernández, Parra Márquez and González, 2009; Moubray, 1997). Tixier, Dusserre, Salvi, and Gaston (2002) notice the difficulty to take in account all risks of an industrial plant and suggest that there is not only one general method to deal with the problematic of industrial risks. Frequently used methods for risk assessment like failure mode and effects and criticality analysis (FMECA), Fine and Kinney method, Fenningkoh and Smith model and risk matrixes as described in the MIL-STD-882E (2012) pursue different goals, ar limited to two criteria or do not take in account all relevant factors that make a device critical for the LCW.

V – Material management

To schedule replacements, deployment of devices and maintenance activities materiel management should be in place. It must be clearly defined in which department devices are used and who is responsible for replacements and the timely execution of maintenance. A good device register is crucial. To make substantiated replacement and maintenance decisions, historical performance and maintenance data should be available for each device.

Source: Defensie.nl

VI – Approach to score device criticality

Literature study showed that the conventional RPN method has been criticized extensively in the literature for a variety of reasons. The main reason is that the mathematical formula for calculating RPN is questionable and debatable. Many researchers apply a scaling method for adjusting inconsistencies by using the normalized eigenvector corresponding to maximum eigenvalue. This method can significantly reduce inconsistencies. Saaty (1990) proposes a theory of pairwise comparisons which relies on the experts judgements to obtain priority scales. This methods helps eliminating bias and moves towards more rational decision making. Two types of measurement can be employed; relative and absolute measurements.

VII – Methodology to prioritize devices by criticality

The problem of prioritizing devices to their criticality for operations is considered to be a multi criteria decision making problem (MCDM). The AHP model is used to solve this. The AHP model determines and expresses, based on expert opinions, mutual interest of criteria in relation to their goal. This information is commonly implicit and therefore not available or known within the organization. AHP is a MCDM tool and uses pairwise comparisons to obtain weighted scores for criteria. In 2006, Vaidya and Kumar analysed the AHP methodology for different applications and found that the specialty of AHP is its flexibility to be integrated with different techniques like linear programming and fuzzy logic. If criteria are added or deleted from the hierarchy structure, goals change or a new decision maker is appointed, the weight or relative importance of a criterion is easily recalculated.

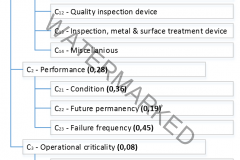

VIII – Model for prioritization of devices

The first objective is to identify and rank the criticality of devices for operations. The outcome of this ranking defines the order of decision making for replacements, adjusting maintenance concepts or to adjust or arrange assortment management. The criteria mentioned by interviewed staff members ar considered to be most valuable. They identify the criteria that make a device critical for the LCW and are preferred to the more general criteria mentioned in literature research. All predetermined criteria were described and a hierarchy tree was made. Several decision makers performed pairwise comparisons on all levels of the hierarchy tree and their geometric weighted scores are used in the model. This also provides insight into the rationale on which these different decision makers weight criteria to determine criticality.

The first objective is to identify and rank the criticality of devices for operations. The outcome of this ranking defines the order of decision making for replacements, adjusting maintenance concepts or to adjust or arrange assortment management. The criteria mentioned by interviewed staff members ar considered to be most valuable. They identify the criteria that make a device critical for the LCW and are preferred to the more general criteria mentioned in literature research. All predetermined criteria were described and a hierarchy tree was made. Several decision makers performed pairwise comparisons on all levels of the hierarchy tree and their geometric weighted scores are used in the model. This also provides insight into the rationale on which these different decision makers weigh criteria to determine criticality.

Devices were assessed on the lowest level of the hierarchy tree using score guides with grades and intensities

for all the sub criteria. After criticality scores are calculated devices can be ranked according to their criticality for operations.

Click to enlarge

normalized by dividing the total score values by the maximum of all devices’ score values.

IX – Decision making information

To rank devices in the order to make replacement or maintenance concept adjustments, decisions heuristic reasoning is performed. Score values of predefined criteria are used as a decision factor with respect to a criterion or a combination of criteria (antecedent or IF-statement) and the consequence (THEN-statement).

Click to enlarge

To rank devices in the order to arrange assortment management decisions, devices are compared to ranked assortment management criteria. Maintenance concepts should be improved if it is considered that the failure frequency is too high over time. And if a failure occurs the downtime can have negative impact on operations. The score values of failure frequency and downtime are considered to be the decision factors to make maintenance concept adjustment decisions and can be deducted as follows:

IF the Failure frequency is high AND the Downtime is high THEN the maintenance concept should be improved.

The score values of the decision factors are ranked from high to low, starting with the failure frequency and then downtime.

Click to enlarge

Within the Airforce replacements should be considered when devices are expected to be (almost) at the end of their technical lifecycle. The importance of operational downtime after failure depends on the redundancy of such devices in the total system. The score values of future permanency and the availability of alternative devices are considered to be the decision factors to make maintenance concept adjustment decisions and can be deducted as follows

IF the Future permanency is low AND the Availability of alternative devices is low THEN replacement should be considered.

The score values of the decision factors are ranked from high to low, starting with the future permanency and then the availability of alternative devices.

Click to enlarge

Each device is compared to the identified singular criterion for assortment management. The assortment management criteria were ordered according to their computed weight, from high to low. Then the individual risk scores of the criteria were sorted from high to low.

![]()

Tags: Article, Assetmanagment, Risk