- Publicatie 24 April 2022

![]()

Instabilities and failure in many industrial structures can be too costly. That includes the pipeline structures for oil and gas industries or power generation plans and infrastructural transit systems. Prognostics and health management, along with Preventive, predictive, and prescriptive maintenance, are alternative options to avoid the failure in these systems by smart and on-time maintenance. However, although it is possible to collect data dynamically from these systems through their service periods, in many cases, a trustworthy and reliable knowledge base to allow making the right decisions is not always available.

This paper presents the concept of LIVE Digital Twin that relies on four phases of Learn, Identify, Verify, Extend employing various Computer-Aided Engineering (CAE) simulation strategies during the life span of the structure parallel to its design, performance, inspection, and maintenance. The architecture of LIVE Digital Twin is presented, and the details are described along with some practical case studies in Light Rail Transit (LRT) and pipeline systems in oil and gas industries. The presented concept and architecture of LIVE Digital Twin can be employed and implemented for various other applications and non-structural systems.

![]()

Authos: N.G. Malek Kheli, M. Tayefeh, A. Barari and Dylan Bender

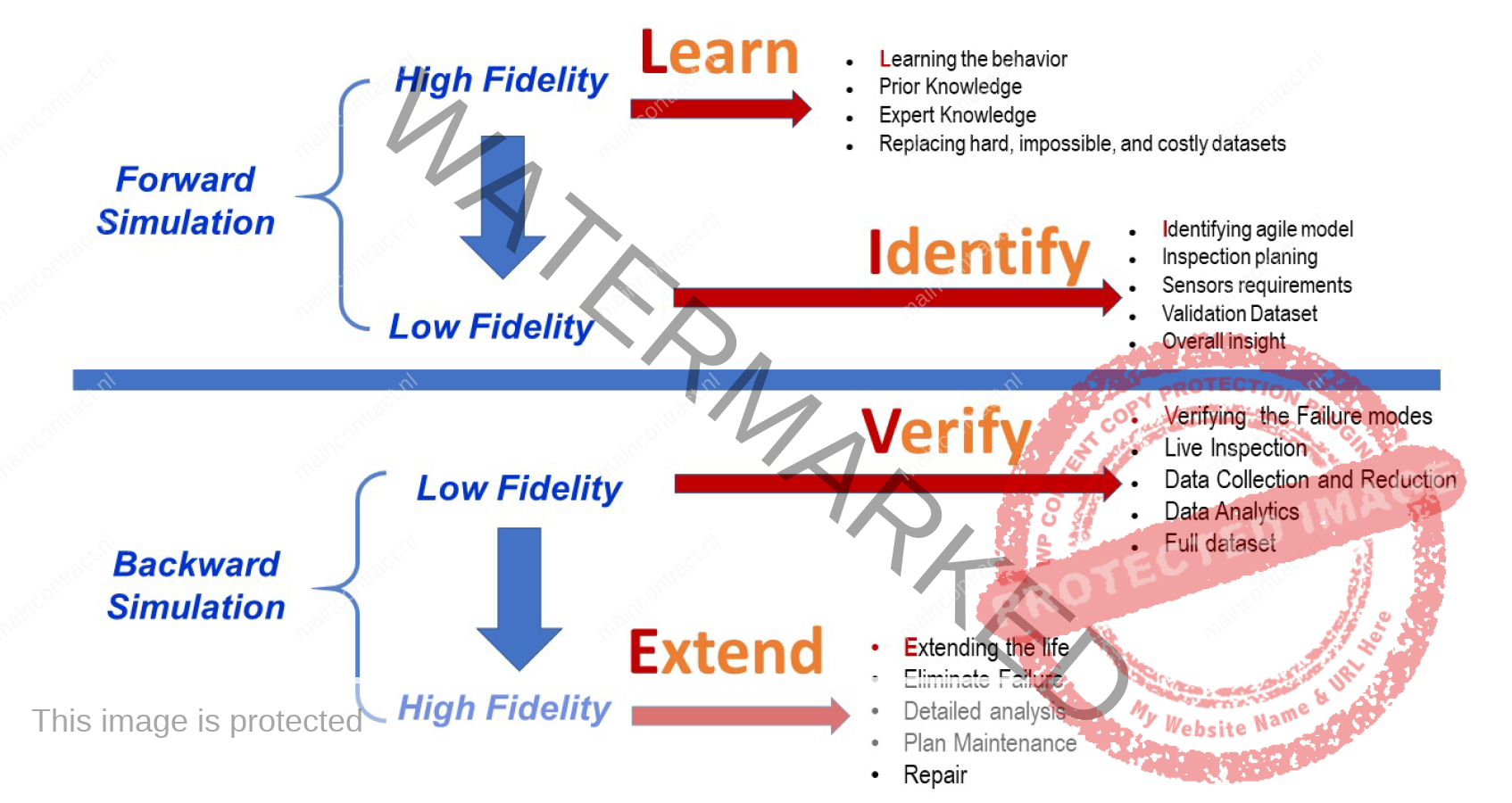

LIVE Digital Twin refers to four phases of Learning, Identifying, Verifying, and Extending for a physical asset. Figure 1 demonstrates the DT platform with a combination of these four phases. LIVE digital twins are alive using the power of simulation. Multi-physics simulations are performed dynamically through the life span of the digital twin to support each of the Learning, Identifying, Verifying, and Extending phases. A simulation provides a knowledge transformation. It transfers the input to a physical asset to the knowledge regarding its output, or vice versa

The input knowledge includes the expected and unexpected impacts on the physical asset and its boundary condition. An example of the expected inputs are the external loads to a physical structure, and the example of the unexpected impacts are the loads and deformation applied to the structure due to damages and defects. The boundary condition defines the constraints and the limitations of the physical asset, e.g., the type and location of the supports for a structural system.

![]()

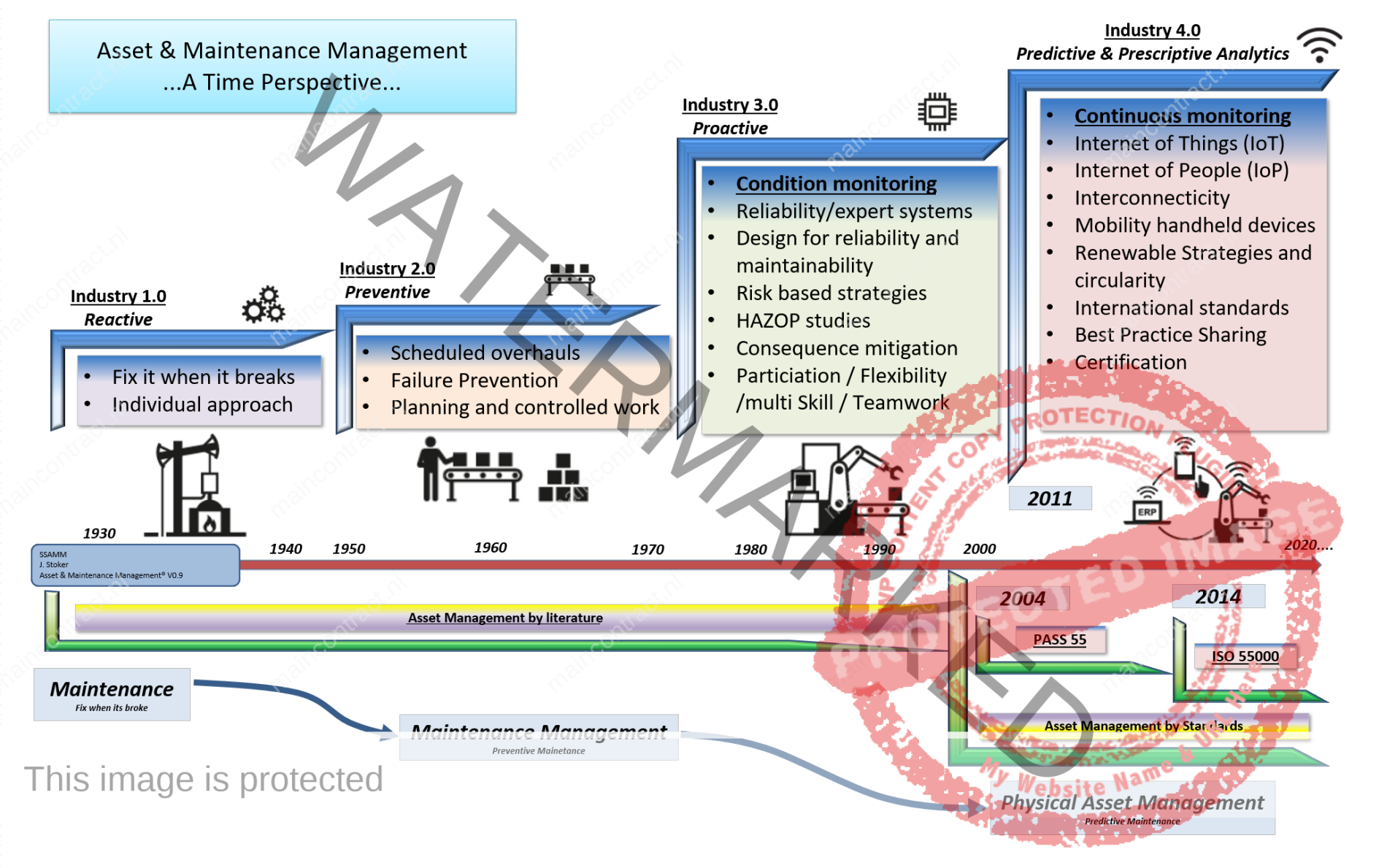

Click to enlarge: Asset & Maintenanec Management-A time perspective by Jan Stoker

The output of the physical system is the resulting performance of the system for the given input, for example, the resulting deflection or stress on the components of a structure subjected to certain loading conditions. Although all the simulations in four phases of LIVE DT are based on the same Multiphysics, however, there are performed in two different levels and two different modes, as shown in Figure. The levels and modes of the simulation are described as follows:

- Forward simulation (FW) mode: a transfer of knowledge from a set of input information to output information.

- Backward (BW) simulation mode: a transfer of knowledge from a set of output information to input information

- High-Fidelity (HF) simulation: High-Fidelity simulation is a simulation that involves the use of a sophisticated solver and full details of the model to result in a life-like output for a given set of inputs.

- Low-Fidelity (LF) simulation: Low-Fidelity simulation is a simulation that involves the use of a simplified solver without considering the full details of the model to result in a fast approximation of the response of the system.

The employed Model-Level combinations from phase one to phase four of LIVE DT are FW-HF, FW, LF, BW-LF, and BW-HF.

![]()

The recently published standard EN 17485 introduces methods and procedures about maintenance within physical asset management for all the levels and functions of the organizations’ management, including corporate planning management, plant management, technical management, production management, financial management, asset management, maintenance management, and quality management. Further and maybe even greater benefits are now being found through improved credibility in the eyes of customers, regulators and other stakeholders.

Click to enlarge

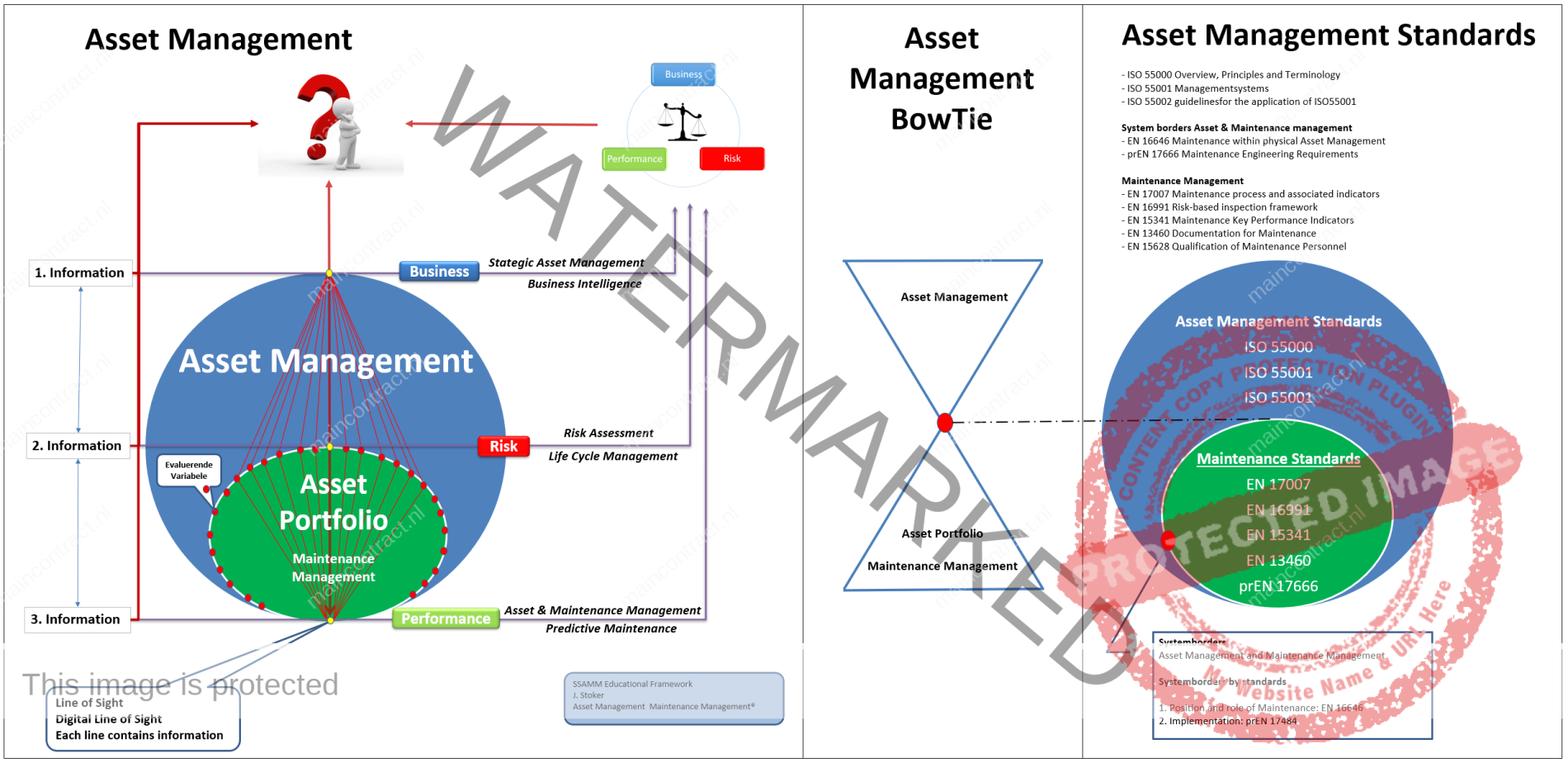

Physical asset management also results in much greater engagement and motivation of the workforce, and in more sustainable, continual improvement business processes. Physical asset management builds up the required link between maintenance management and the organizational strategic plan and gives direction to maintenance activities.The standards EN 16646 and EN 17485 build the bridge between ISO 5500x (Asset management system standards) and the EN maintenance standards. ISO 55001 states that organizations should determine e.g. the organizational context, requirements for the assets, decision criteria, strategic asset management plan and asset management plan (including maintenance).

However, it does not describe how to do it. Respectively, maintenance standards often introduce e.g. the concept of the required function or the concept of maintenance strategy, but do not explain how they have been determined. EN 17485 introduces a methodological framework which advises organizations to implement the requirements presented in ISO 55001. By doing this it creates the bridge between the several maintenance standards and ISO 5500x in order to give an applicable starting point to the more detailed documents for the specific sub-functions of maintenance (See AM-BowTie).

This insights, the Asset Management BowTie, can be added toward the Asset Management paradigm with the (Digital) Line of Sit. To add the BowTie principle, the body of thoughts of the EN-17485 can be incorporated in the Asset Management paradigm with the mentioned standards. Result is a deepened figure 1 of the ISO5500 completed with the Line(s) of Sights, the levels of information, Business, Risk Assessment and Asset & Maintenance going to decision making in balancing Costs, Risks and Performance.

Click to enlare Asset Management BowTie: See Body of thoughts AM-BowTie Click Here

![]()

Learning: The first phase of the LIVE digital twin life span is about learning the behaviors of the system by conducting a combination of forward simulation, experimental data, and theoretical analyses at a high-fidelity level. That will create prior knowledge and expert knowledge required to identify the parameters and characteristics that need to be monitored in the system. A set of algorithmically designed simulations is an efficient replacement for hard-to-implement, impossible, or very costly physical experiments.

Identifying: Following the Learning phase, an agile model of the system is identified by highlighting the critical areas and indicators that monitoring them allows evaluating the health of the systems. The low fidelity simulation required for this phase is developed by highly simplified elements and simulation models. However, the parameters in this simplified model are defined following an optimization process to comply with the results of high-fidelity simulation considering an acceptable tolerance. The inspection procedure is defined, and the position and specification of the sensors required for monitoring are identified in this phase. The LF simulation results are validated with the HF simulation as a direct result of the optimization process. With some available physical asset experiments to ensure the LF simulation can provide a comprehensive insight into the health of the system.

Verifying: The sensors are installed at the identified locations and collect data using the planned inspection procedure during the physical system operation. A cyber component can accompany sensors to perform on-site data analytics. Ideally, in the Verifying phase, the cyber system runs a low fidelity on-site simulation, using the millions of data points captured dynamically from the physical system. That may also result in significant data reduction, which reduces the data transmission cost (Lalehpour et al., 2017). Considering the information produced by the cyber system, the overall health of the physical asset is assessed and using low-fidelity backward simulation, any potential failure mode is verified.

Extending: Utilizing the verified potential failure modes, the objective in the last phase is to extend the life of the physical asset by planning the required maintenance for the predicted failures. That is performed directly using prior knowledge or high-fidelity backward simulation to eliminate potential failure. Instructions for predictive maintenance and repair are produced in this phase.

![]()

5. React, Discuss & Article

Discuss or give your opinionFollow on FacebookFollow on Twitter

Related Articles