Pagina Inhoud

- Publicatie 8 Januari 2022

![]()

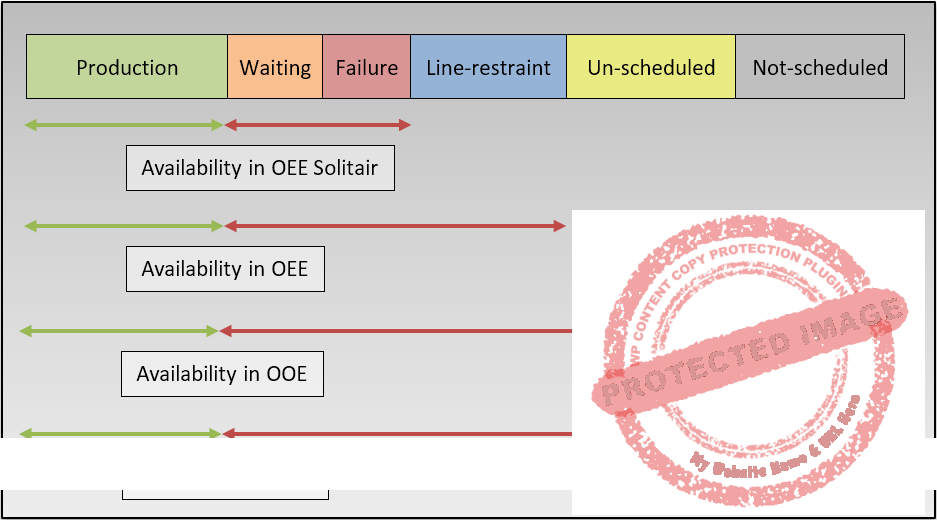

Several parties, such as production teams, line managers and top management may have a different scope when looking at ‘effectiveness’. Being aware of those differences, it is possible to calculate different indices representing those different scopes; all based upon the same data. In the literature we find several attempts to do so, unfortunately they are not always consistent. Although these definitions go beyond the scope of OEE, it is necessary to have a clear picture on this issue since it determines how to define certain categories within the OEE.

![]()

Source: OEE Coach

Defenition of Availability in OEE

In the definition of OEE, the ‘availability rate’ indicates the relationship between the time that the machine could theoretically have been in operation (there was ‘demand’) and the time that there was actual output.

OEE TOP

OEE Top is equal to OEE, except for the way the performance rate is calculated. In OEE Top the performance rate is calculated based upon the Name Plate Capacity of the equipment; thus ignoring restraints due to the product-machine combination. It is used to detect effectiveness losses due to the allocation of products; the chosen product mix.

OEE Top is used in systems where the physical maximum of the equipment and the physical maximum of certain products are far apart. If for example an extruder has enough heating and extrusion power to produce a 125mm PVC pipe and you would now produce a 15mm pipe, then its maximum speed in kg of product would be significantly lower than for this 15 mm pipe, although it is physically driven to its limit.

In other words: it would be better to produce this smaller pipe on a smaller extruder. So if the OEE is significantly higher than the OEE Top, then could ask yourselves whether you may have used an oversized system for the current product mix.

OEE Solitaire

OEE Solitaire is applicable in situations where the monitored equipment has a (technical) link to other equipment/processes. Thus the equipment is an integrated part of a line. The effectiveness of such equipment is partially depending on factors like line balance and effectiveness of other equipment. OEE Solitair is is meant to detect the influence of line dynamics to the equipment.

‘No Input’ (input buffer empty) and ‘No Output’ (Output buffer full) are the exponents of such influences.

In certain cases i.e. with huge installations in process industry, or lines with V-shape characteristics, parties may want to know the effectiveness of some of the equipment independently from the rest of the process. The resulting effectiveness losses are so to say collateral damage from issues outside the monitored equipment. In other words; What would the effectiveness of the equipment be, when it was running solitaire, with no restraints from the rest of the line?

Definition of Availability in OEE Solitair

For this purpose, an OEE can be calculated excluding ‘No Input’ and ‘No Output’ thus showing the effectiveness purely focussed on the equipment independent from the line. Calculating the OEE Solitaire takes Line restraint time (normally considered to be (I) Idle time) out of the loading time (so it is considered as Unscheduled time (-) ).

Operations effectiveness goes beyond the scope of the production team (Maintenance – Operator – Engineer). It includes the operations time the equipment is not available to the production team or when operations management does not want or cannot schedule the equipment. Examples are ‘No Orders’, ‘Legal Restrictions’ like energy contracts and mandatory holidays and test runs for R&D.

![]()

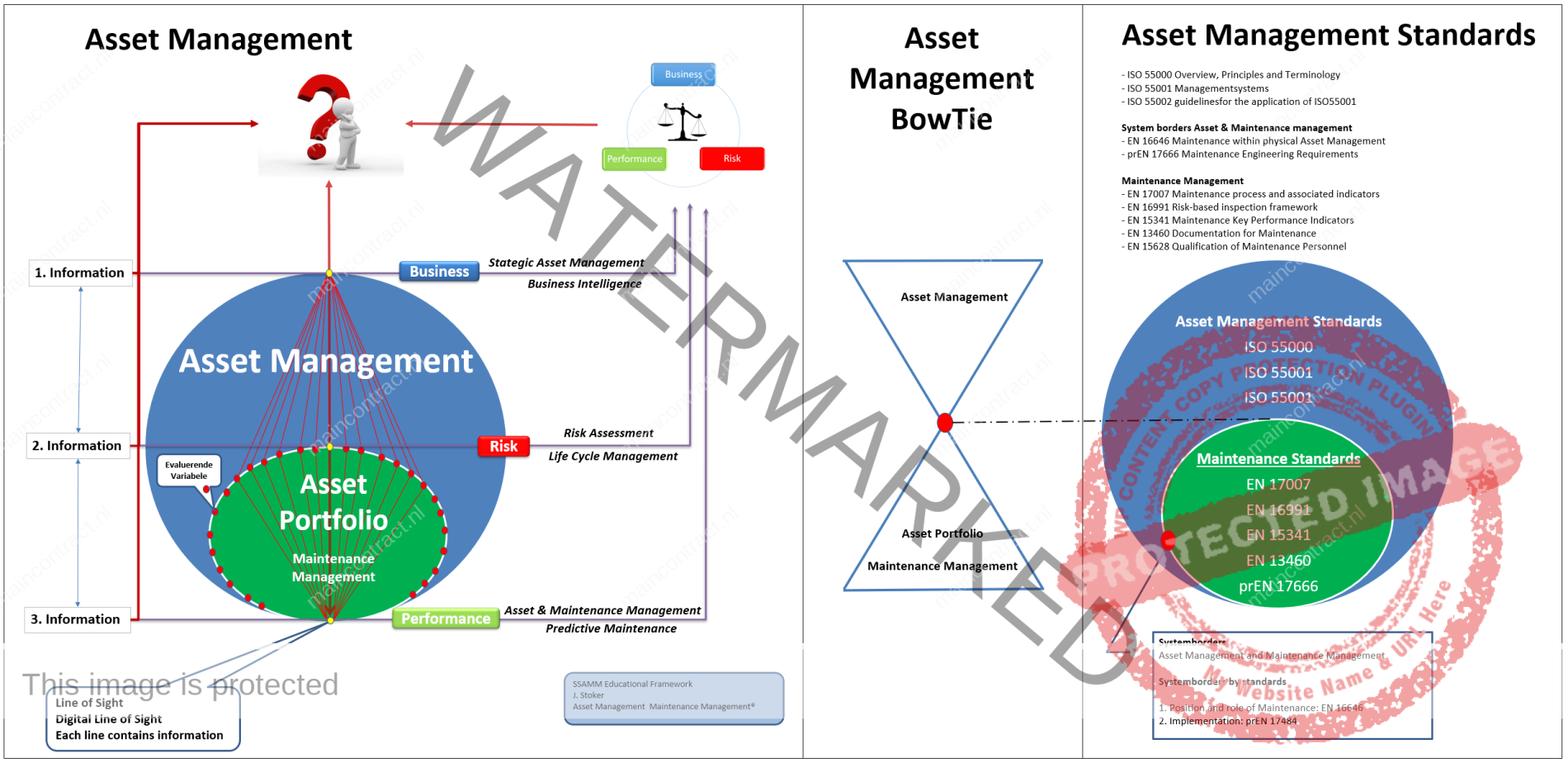

Intermezzo The Asset Management BowTie

The recently published standard EN 17485 introduces methods and procedures about maintenance within physical asset management for all the levels and functions of the organizations’ management, including corporate planning management, plant management, technical management, production management, financial management, asset management, maintenance management, and quality management.

Further and maybe even greater benefits are now being found through improved credibility in the eyes of customers, regulators and other stakeholders. Physical asset management also results in much greater engagement and motivation of the workforce, and in more sustainable, continual improvement business processes. Physical asset management builds up the required link between maintenance management and the organizational strategic plan and gives direction to maintenance activities.The standards EN 16646 and EN 17485 build the bridge between ISO 5500x (Asset management system standards) and the EN maintenance standards. ISO 55001 states that organizations should determine e.g. the organizational context, requirements for the assets, decision criteria, strategic asset management plan and asset management plan (including maintenance). However, it does not describe how to do it. Respectively, maintenance standards often introduce e.g. the concept of the required function or the concept of maintenance strategy, but do not explain how they have been determined. EN 17485 introduces a methodological framework which advises organizations to implement the requirements presented in ISO 55001. By doing this it creates the bridge between the several maintenance standards and ISO 5500x in order to give an applicable starting point to the more detailed documents for the specific sub-functions of maintenance (See AM-BowTie).

This insights, the Asset Management BowTie, can be added toward the Asset Management paradigm with the (Digital) Line of Sit. To add the BowTie principle, the body of thoughts of the EN-17485 can be incorporated in the Asset Management paradigm with the mentioned standards. Result is a deepened figure 1 of the ISO5500 completed with the Line(s) of Sights, the levels of information, Business, Risk Assessment and Asset & Maintenance going to decision making in balancing Costs, Risks and Performance. The Asset Management BowTie show how standards can be uses as a reference framework.

Click to enlare Asset Management BowTie: See Body of thoughts AM-BowTie Click Here

![]()

Definition of Availability in Operations Effectiveness

In the definition of OOE, regular shift-time that was unscheduled (due to no demand, R&D test runs etc.) from the regular shift time is taken into the KPI. In OEE it is being excluded from availability since this is something that happens outside the scope of the shopfloor-team responsible for the OEE. However, since it is an operations management loss, it is being included in the availability rate of the Overall Operations Effectiveness (OOE).

Definition of availability in TEEP

In the definition of TEEP the question is no longer whether there was ‘demand’. The time that the machine could theoretically haven been in operation is simply 24×7, regardless whether there was demand or whether it was scheduled to run or not.

This leads to the following situation:

- Performance- and Quality Rates remain the same in OEE and TEEP

- ‘OEE availability’ and ‘TEEP availability’ are (usually) different values due to its different horizons of 100% (since TEEP includes unscheduled and nonscheduled time.)

Click for the full article OEE Coach

![]()

5. React, Discuss & Article

Discuss or give your opinionFollow on FacebookFollow on Twitter

Related Articles

Tags: Circulair