Pagina Inhoud

![]()

This report discusses the best practice for the application of Risk Based Inspection (RBI) as part of plant integrity management, and its inspection strategy for the inspection of pressure equipment and systems that are subject to the requirements for in-service examination under the Pressure Systems Safety Regulations 2000 (PSSR). It can also apply to equipment and systems containing hazardous materials that are inspected as a means to comply with the Control of Major Accident Hazards Regulations (COMAH).

One of the main themes of the report is the amount of information that is known about an item of equipment and conversely the identification of where there is a lack of information, which may make the RBI invalid.

The report considers the application, data requirements, team competences, inspection plan (including NDT techniques and reliability) and overall management of the RBI process.

An audit tool is given in the Appendices order to assist the evaluation the RBI process. This contains a flow diagram followed by a series of questions and a commentary relating to each stage. The commentary summarises the best practice discussed in the main text.

This report and the work it describes were funded by the Health and Safety Executive (HSE). Its contents, including any opinions and/or conclusions expressed, are those of the authors alone and do not necessarily reflect HSE policy.

![]()

Author: TWI and Royal & SunAlliance Enineering

1. Aims and Objectives

Owners and users of plant (‘Duty Holders’ within this report) have the option to manage the integrity of their plant and plan inspection from assessments of the risks of failure. They need to be able to demonstrate that the risk assessment and inspection planning processes are being implemented in an effective and appropriate manner.

The aim of this report is to assist Duty Holders and regulators identify best practice for plant integrity management by risk based inspection (RBI). The Health and Safety Executive (HSE) commissioned this project within its Mainstream Research Programme 1998/99. The specific objectives are:

- To define the process and key elements of RBI.

- To give guidance on the information required and methods for RBI.

- To suggest best practice for the proper implementation of RBI.

- To provide an audit tool to enable evaluation of RBI.

![]()

2. Scope

This report applies to plant integrity management and inspection of pressure equipment and systems that are subject to the requirements for in-service examination under the Pressure Systems Safety Regulations 2000 (PSSR). It also applies to equipment and systems containing hazardous materials that are inspected as a means to comply with the Control of Major Accident Hazards Regulations (COMAH). The principles and practice of RBI within this report are also applicable to the management of other safety-related structures and equipment, for example lifting and fairground equipment.

The report views RBI as one of a range of measures within the wider process of plant integrity management. It evaluates RBI within the context of the current regulatory framework and focuses on the form and management of the RBI process rather than on specific techniques or approaches. After an introductory chapter defining the basis of the report, the following nine chapters deal with the different stages of the process.

An example is given of a risk assessment carried out by Royal and SunAlliance Engineering as an authoritative technical review of examination intervals of a plant. It highlights the importance of the multi-disciplinary team approach to RBI and the role of the Competent Person. It shows how, as a result of the risk assessment, examination intervals could be extended for some items of equipment.

An audit tool is given in order to assist Duty Holders and regulators evaluate the process of plant integrity management by RBI. This contains a flow diagram followed by a series of questions and a commentary relating to each stage. The commentary summarises the best practice discussed in the main text.

Duty Holders inspect plant to manage the risk of failure for many reasons. Whilst this report is primarily concerned with risks to Health and Safety, it recognises the responsibilities of Duty Holders to protect the environment and manage their business effectively and efficiently. The common goal is to prevent failure that could cause danger and damage.

3. Main Themes

One of the main themes of the report is the amount of information that is known about an item of equipment and conversely the identification of where there is a lack of information. Even when information appears to be known, the risk based approach requires that the quality and veracity of the information is tested and validated. Risk is increased when there is lack of, or uncertainty in, the key information required to assess integrity.

In terms of plant integrity, key information is generated from the design, operational experience and inspection records, and knowledge of the deterioration mechanisms and the rate at which deterioration will proceed. This knowledge enables current and future fitness-for-service to be assessed. Inspections can then be planned at appropriate intervals using inspection methods that are able to detect the type and level of deterioration anticipated.

The PSSR enable a risk-based approach to be used for the planning of inspection. As goal-setting regulations, they allow the Duty Holder and Competent Person flexibility in deciding upon a suitable written scheme of examination in terms of the equipment to be inspected and the frequency and nature of examination. The information generated by the risk assessment can be used to aid these judgements and to achieve a safe and suitable scheme that is not unduly restrictive.

The report discusses the capability of various NDT methods and the means that Duty Holders can use to assure themselves of the reliability of their inspections. The status of acoustic emission, long range ultrasonic and other remote and non-invasive techniques is reviewed, together with the benefits of inspection qualification.

Risk changes with time either because the equipment or plant conditions physically alter, or because new information becomes available. The report highlights the importance of feedback and the re-assessment of risk during plant life. This is particularly pertinent when inspection intervals are long.

4. Application

The report will be of use to engineers responsible for planning inspection of safety critical plant. Regulators, safety managers, site inspectors and others involved in industrial risk assessment will also find the report useful.

The advice given in the report is not intended to be prescriptive, but to be used as a guide to best practice, to be adapted to suit specific circumstances, and to be interpreted in terms of a goalsetting safety regime.

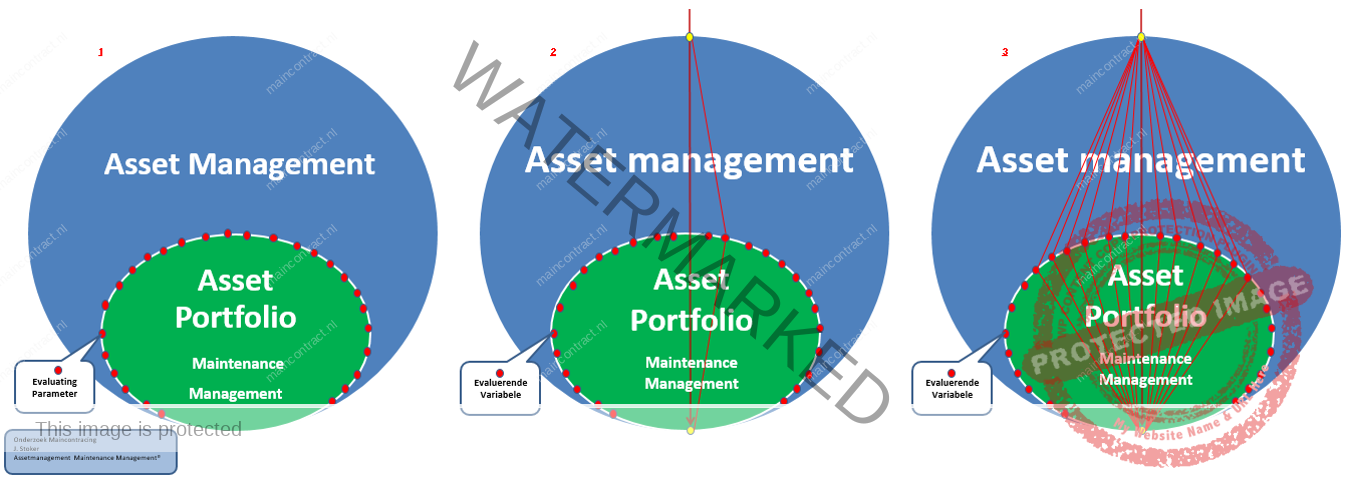

Asset Management Systems: See The Line of Sight-Deepening the subject

![]()

Klik hier voor het volledige artikelDiscuss or give your opinionFollow on FacebookFollow on Twitter

Verwante Artikelen